Reshoring Manufacturing: Why Arizona’s Industrial Sector is Set to Shine

Manufacturing is returning home, plain and simple. Companies are tired of offshore headaches, and reshoring is the fix. For Arizona—where industry runs deep and the business climate achieves results—this shift means big-time opportunities. Arizona manufacturers are ready to grab the reins and make the most of this reshoring wave. Why Reshoring Matters Reshoring isn’t a […]

Additive Manufacturing Meets Traditional Processes: The Future of Brazing and Heat Treating

There’s been a lot of chatter about new technology in manufacturing, but here’s the bottom line: The fusion of cutting-edge techniques like additive manufacturing with time-tested processes like brazing and heat treating is turning the industry on its head. If you’re a durable goods manufacturer who wants to stay relevant, you can’t sit on the […]

How Golf Clubs Benefit from Aerospace Technology

Aerospace technology isn’t just for rockets anymore. It’s reshaping how golf clubs and other durable goods are manufactured. The same materials and processes that keep satellites in orbit are giving manufacturers an edge in product development. By applying space-grade materials, precision manufacturing, and rigorous testing, golf club manufacturers are not only enhancing product performance but […]

Great Manufacturing Starts with Great Engineering

When you craft metal parts, engineering is everything. From casting and forging to machining and brazing, every phase of the engineering and production process is packed with its own challenges. Getting each one right is critical for building components that withstand the test of time, especially when brazing is part of the process. Precision Matters […]

The Essentials of Building an Ironclad Fabrication Process

Crafting an ironclad fabrication chain that can weather any storm is essential for manufacturers. This is especially true when it comes to manufacturing complex metallurgical products like artificial hip joints and aircraft wings. In these industries, there is zero room for error. Every step, from wrangling raw materials to dispatching finished products, is fraught with […]

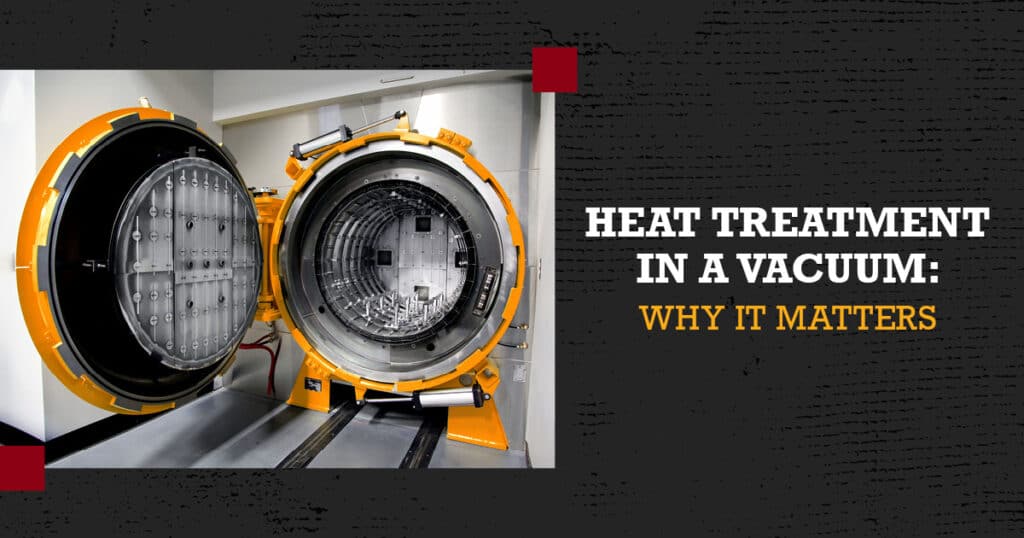

The Vacuum Heat Treating Advantage: A Blueprint for Manufacturing Success

Excellence is always nonnegotiable in the world of durable goods manufacturing. Among the arsenal of techniques that fuel the pursuit of manufacturing excellence, vacuum heat treating shines as a beacon of precision and quality. Its role goes beyond mere heat treating. It’s a transformative force that elevates product quality, fortifies mechanical properties, ensures versatility and […]

Repeatability Reigns: Elevating Brazing to Unprecedented Standards

In the precision-driven sphere of manufacturing, reliability and precision are nonnegotiables. Whether it’s in crafting surgical and implant devices, transportation components, or aviation essentials, the demand for consistent, top-tier metal parts reigns supreme. Brazing emerges as the go-to process for achieving such precision and reliability in joining metal parts. Yet the success of brazing isn’t […]

What to Look for When Choosing a Metalworks Partner

Whether you’re engineering golf clubs capable of acing shots from distant fairways, creating components for cosmic space odysseys, or dreaming up the most extravagant fountain pens in the universe, you deserve a metal treatment partner that personifies precision, reliability, experience, and technical expertise. That’s why it’s important to carefully consider a variety of factors in […]

Striking the Perfect Balance of Speed and Quality in Metal Parts Fabrication

In the world of metal parts fabrication, speed and quality are often seen as bitter rivals in a never-ending battle for supremacy. If you dare to dream of high-quality brazing and heat treating, be prepared to sacrifice speed at the altar. If you have a need for speed, brace yourself for a heartbreaking compromise on […]

Building Safety into Fabrication Project Planning

Full fabrication process management is all about controlling risks. The distributed manufacturing model strings together specialized suppliers across hundreds or even thousands of miles. A lot can go wrong along the way, which is why vendor selection and oversight are so important. Safety is a bedrock issue for risk management. Everyone understands the importance of […]