Peering Beneath the Surface: Harnessing X-Ray Testing for Brazing Brilliance

Brazing is far from a walk in the park. It’s a waltz of precision where every step counts. One wrong move and you could be face to face with a potential disaster. That’s where X-ray testing enters the picture, revealing the hidden flaws that could turn a masterpiece of ingenuity into a mess. Unveiling the […]

The Essentials of Building an Ironclad Fabrication Process

Crafting an ironclad fabrication chain that can weather any storm is essential for manufacturers. This is especially true when it comes to manufacturing complex metallurgical products like artificial hip joints and aircraft wings. In these industries, there is zero room for error. Every step, from wrangling raw materials to dispatching finished products, is fraught with […]

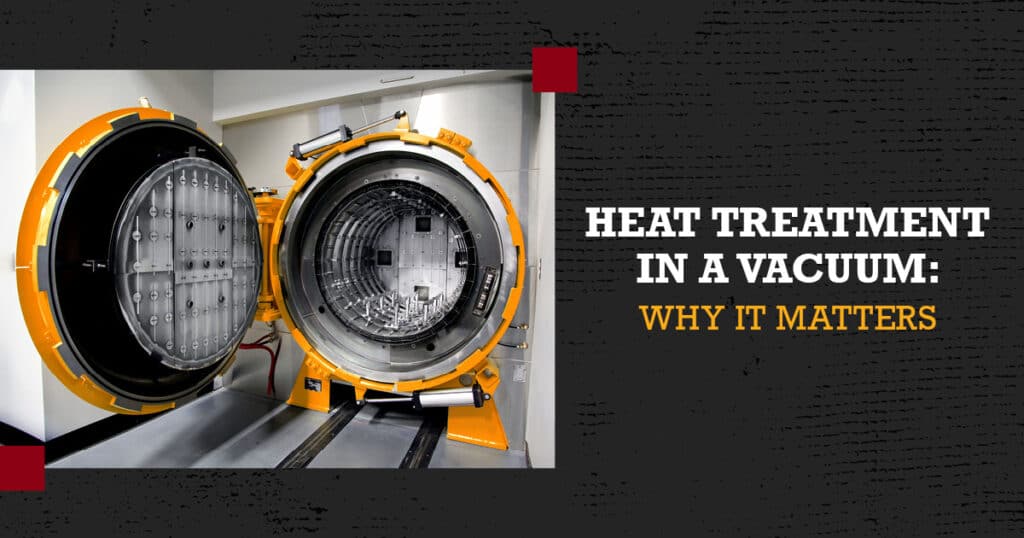

The Vacuum Heat Treating Advantage: A Blueprint for Manufacturing Success

Excellence is always nonnegotiable in the world of durable goods manufacturing. Among the arsenal of techniques that fuel the pursuit of manufacturing excellence, vacuum heat treating shines as a beacon of precision and quality. Its role goes beyond mere heat treating. It’s a transformative force that elevates product quality, fortifies mechanical properties, ensures versatility and […]

Repeatability Reigns: Elevating Brazing to Unprecedented Standards

In the precision-driven sphere of manufacturing, reliability and precision are nonnegotiables. Whether it’s in crafting surgical and implant devices, transportation components, or aviation essentials, the demand for consistent, top-tier metal parts reigns supreme. Brazing emerges as the go-to process for achieving such precision and reliability in joining metal parts. Yet the success of brazing isn’t […]

Our Place in Arizona’s Manufacturing Sector Our Name Says It All

In the rugged terrain of Arizona’s economic landscape, Legacy Brazing burns brightly as a testament to grit, determination, and the relentless pursuit of manufacturing excellence. Our name reflects deep roots in an industry that has been the foundation of a family obsession for over four decades. We’re proud to bring those traditions to northern Arizona. Forging […]

From Raw to Refined—Five Essentials for Choosing a Metal Treatment Partner

Every detail of your manufacturing process holds the potential to make or break the success of your project. From the raw materials to the final product, the life cycle your metal components undergo plays a vital role in your product’s commercial success. Every grind, every burn, every bend in the process shapes the success of […]

What to Look for When Choosing a Metalworks Partner

Whether you’re engineering golf clubs capable of acing shots from distant fairways, creating components for cosmic space odysseys, or dreaming up the most extravagant fountain pens in the universe, you deserve a metal treatment partner that personifies precision, reliability, experience, and technical expertise. That’s why it’s important to carefully consider a variety of factors in […]

Three Keys for Unfinished Goods Transportation

In the unforgiving world of durable goods manufacturing, the journey from raw materials to polished, ready-for-market goods is the bedrock of your success. It’s about making quality metal parts and safeguarding them during their journey. That’s why you need a raw materials treatment partner who doesn’t just excel in fabrication, treatment, and testing but also […]

The Mystery Unveiled: Mastering the Art of Brazing with Specialty Materials

Unlocking the full potential of exotic materials and alloys is the key to groundbreaking products. Titanium, Inconels, and niobium—the revered stars of engineering—possess unique properties that drive modern advancements. However, for the uninitiated, brazing these gems can pose formidable challenges. Modern manufacturing advancements often hinge on the unique properties of exotic materials, and alloys like […]

The Secrets Behind Durable Brazed Joint Connections

Brazed joints, the unsung heroes of industries like automotive and aerospace, connect metal parts and promise durability, but here’s the kicker: These joints need to be as reliable as your morning coffee, or they could spell disaster. So testing them is a big deal in all industries, especially in industries like aerospace, automotive, and medical […]